1、 0.2 level high-precision intelligent control matrix belt scale

The high-precision fully intelligent matrix electronic belt scale produced by Yike Company adopts advanced artificial intelligence weighing technology, matched with specific ultra-high sensitivity balance sensors and artificial intelligence weighing controllers. It adopts multiple sets of AD matrix arrangement, and the system weighing accuracy is up to ± 0.2%. The stability cycle of one calibration can be more than 6 months. Self inspection and self calibration, maintenance free and long-term stability, can achieve worry free measurement!

2、 Intelligent matrix algorithm for AD detection and cycle comparison

Equipped with a unique artificial intelligence matrix algorithm and an intelligent calibration system, each sensor is individually AD detected, cycle compared, fault alarm, and out of tolerance removed. The operation status and environmental temperature of the entire conveyor are included in the calculation, ensuring that the belt scale always maintains high-precision and high stability operation.

3、 Matrix Control Tracking Review Operating State Self Verification

The automatic calibration device is installed on the main body of the electronic belt scale, with a proprietary structure that can simulate the gravity state of the transported material. It automatically completes the full state calibration of the belt scale, using the SEQ-AI intelligent algorithm and matrix control tracking and review technology. It automatically completes monitoring and calibration correction in operation and use.

4、 0.2 level belt scale qualification certification

Type Approval Certificate of Class 0.2 Measuring Instruments of the China No. 2018FC0011-32

Member unit of China Weighing Instrument Association

High precision belt scale patent group

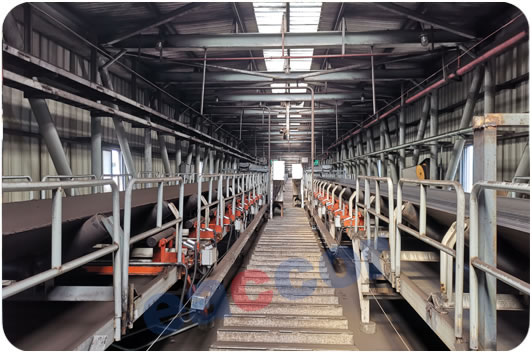

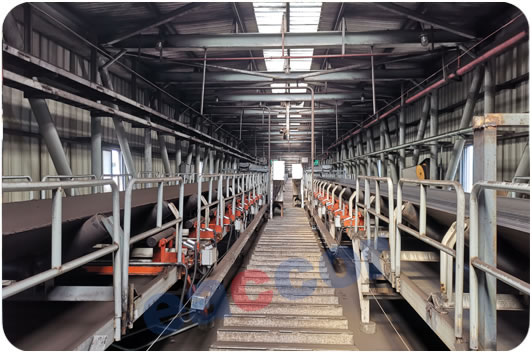

5、 Intelligent Control Matrix Belt Scale System

Principle of Intelligent Control Matrix Belt Scale

5、 Intelligent Control Matrix Belt Scale System

Principle of Intelligent Control Matrix Belt Scale

Eight to thirty-two sets of modular scale bodies can be verified for mutual redundancy, and matrix modular scale bodies can all adopt electric automatic code hanging verification without the need for manual work. Modular scales can be used in sequence intervals, and combined with matrix intelligent weighing instruments, they are divided into two sets of scales within the system.

Among the eight to thirty-two modular scales, n/2+1 groups (with high serial numbers) are equipped with electric takeoff and landing devices to achieve online verification of dual scales within the system, automatic correction of system accuracy, self judgment of accuracy status, and self correction.

6、 Stress balanced load cell

6、 Stress balanced load cell

The high-precision sensor dedicated to the single point suspension weighing platform has a unique structure and features high weighing accuracy and strong resistance to horizontal force interference. It meets the C6 level of OIML weighing sensors and is far superior to other C3 level sensors used in belt scales.

The high-precision weighing sensor adopts matrix balanced OMIE C6

At present, the sensors used in the market for belt weighers are mostly resistance strain type weighing sensors. However, resistance strain type weighing sensors have the phenomenon of sensitivity drift with changes in environmental temperature. Therefore, resistance strain type weighing sensors without temperature compensation will change their output accuracy with changes in temperature.

7、 High precision belt scale dedicated intelligent matrix instrument

7、 High precision belt scale dedicated intelligent matrix instrument

8-32 independent AD digital inputs, real-time monitoring of each AD, not simply averaging, but processing through the PEL intelligent data model system;

Automatically shield the out of tolerance Matrix unit, give an alarm to the matrix scale group that finds problems, and automatically shield the faulty weighing sensor signal to realize continuous high-precision weighing;

The weighing instrument has advanced and unique 32-bit A/D conversion technology, which has high accuracy, fast speed, low temperature drift, and long-term stability and reliability;

The movable P-Module chip card stores calibration data, stores data, and after replacing the spare instrument, directly inserts a new table without the need for recalibration. The core patented technology;

220VAC power supply, high integrated circuit, strong electromagnetic shielding and anti-interference ability;

The intelligent instrument system will perform cloud processing on each calibration data and the data generated during use, and self track and correct it.

High definition color touch screen display, in both Chinese and English

Relative humidity: up to 95%, without condensation.

Accuracy: The error between -40 ℃ and+50 ℃ is within 0.012% of the weighing sensor range.

Linearity: better than 0.01% of net weight, with 120% input from no load to full load

8、 High precision digital signal collector for electronic belt scale

8、 High precision digital signal collector for electronic belt scale

The digital signal collector serves as the link between the weighing unit and the multi-channel intelligent instrument, providing excitation for the weighing sensor and converting the analog signal output by the weighing sensor into real-time digital signals.

9、 Environmental temperature sensor

A proprietary temperature detection unit that converts environmental temperature changes into digital signals and sends them to intelligent instruments.

10、 Speed sensor

Intelligent control matrix scale dedicated speed sensor, mounted on top. It adopts a uniquely made high-precision dedicated speed measuring roller that contacts the lower surface of the conveyor belt, ensuring a seamless match between the measured speed and the weighing area of the carrier, and eliminating any slipping opportunities of the belt.

11、 ECO Electronic Leather Scale Matrix Scale IoT

11、 ECO Electronic Leather Scale Matrix Scale IoT

Matrix scale IoT management function

1. It can monitor the status of the matrix scale in real-time.

2. Operation data of each Matrix unit.

3. Real time temperature monitoring on site, compensating for data tracking compliance.

4. Alarm for out of tolerance, monitor self calibration results, or contact after-sales service.

5. Pre diagnose sensor faults, notify users and provide after-sales solutions.

6. Intelligent Control Cloud Brain automatically improves system accuracy and stability cycle by analyzing on-site operation data, tracking curve changes, comparing and verifying data.

Technical parameters of intelligent control matrix belt scale

|

Rated flow rate

|

10t/h-20000t/h

|

|

Physical verification error

|

Number of unitsn=8/10/12/16/24/32

≤±0.1%(Secondary inspection)

≤±0.2%(Usage accuracy)

|

|

Number of Matrix unit

|

n≤32

|

|

Effective weighing section length

|

Ln(L:idler spacing)

|

|

belt width

|

500-2800mm

|

|

belt speed

|

0.01-6m/s

|

|

Optional high stability process scale

|

Number of units n=4, usage accuracy 0.5%

Number of units n=6, usage accuracy 0.3%

|

English

English 中文

中文